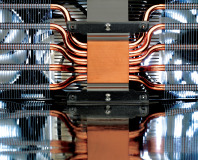

BlastFlow Siberian Modular VGA Waterblock

September 1, 2007 | 04:34

Testing:

We tested the BlastFlow Siberian against a Danger Den DD-8800GTX with a Corsair Nautilus that used 3/8th hose. Only the waterblock was on the loop, the CPU and other components were cooled normally with heatsinks and air.The DangerDen block was the same that came with the BFG 8800 GTX we reviewed at the very start of the year. BFG actually told us know that we're using the best clocking card it's seen, at least in the UK, as this will do 687MHz - a far cry above even the 612MHz Ultra clock speeds.

We sat the card on the Windows Vista desktop for an Idle reading, then ran 3DMark06 graphics tests to stress the card in order to test the temperature at load. We read the internal temperatures with the onboard sensors using Riva Tuner and took an average over several minutes of activity.

Results:

The BlastFlow Siberian out performs the Danger Den block in all accounts by a margin of several degrees. We tried overclocking further given the cooling difference and found that the card was actually now the limit. We tried pushing it hard and it survived about 90 seconds of 3D load at 702MHz core speed before hard locking. In all, the Siberian is clearly a block that can provide some serious cooling performance, even when attached to a mediocre cooling setup.

Value:

The BlastFlow is a "one off" cost of £100 ex VAT - that's block and base, but then you keep the block and simply upgrade the base for a mediocre sum of around £20. £20 compared to £60/80/100+ on top of your new several hundred pound sterling graphics card is much easier to swallow. Plus, the theory is Vadim can turn around a new base far quicker than anyone else can design and mass produce a whole new block. So that's value in time saved, and repeat purchase.The Danger Den 8800 GTX can be had for around £90 although the EK 8800 GTX is just £50-£55. This means the Vadim is now twice the price? You'd have to make sure you'll want to continue using the BlastFlow Siberian well into the next upgrade cycle to make it a cost benefit, but even then two EK's are, at worst, the same as one Siberian, and that's without the extra baseplate upgrade. The initial Siberian purchase ideally needs to be less than £100 to make it really worthwhile.

Initial Thoughts...

The BlastFlow Siberian Modular VGA Waterblock is an interesting and innovative take on high-end graphics card watercooling that shows a lot of promise. However, there are a few issues relating to installation and build quality that mar an otherwise impressive first outing.The block's edges are a little too sharp for our liking and it could lead to someone cutting themselves whilst installing it... which leads us onto the installation procedure itself. The cooling plate is easy enough to install, but it’s after that when the problems start – it was pretty fiddly and required two of us to get the block installed with a good contact - it could be the reason why nobody has gone down this route before.

The finish is a little naff too. If you spend upwards of £100 on a single cooling component you expect it to stand out and look like the money you've splashed out on it. This is completely evident with the Danger Den, but the simple brushed aluminium base plate and lack of core detail makes it seem underwhelming. The concept is a really bright idea, and simple base plates keep the cost as low as possible while keeping the cooling to the max. After all, once it's in a case who's going to see it if it's facing the floor?

What we're really wondering is how well (if at all) Vadim can see into the future? What's to stop ATI or Nvidia decide the don't want to put screw holes in the corners around the GPU anymore? They've done so consistently to date but graphics design is a lot more liberal in some respects than CPU - the whole cost-benefit of the main waterblock could be killed in a single product cycle. However, that shouldn't be the case any time soon as Nvidia is early into its mid-cycle and ATI is early-cycle, and neither company has had its DirectX 10 refresh yet. So, the block should still provide an ample investment.

The concept of a modular block means it's also resellable - so you're more likely to invest in it in the first place, even if you chose not to continue with watercooling at your next upgrade cycle. Your investor can then just grab a base plate for a little cost and the whole process keeps on rolling. The only worry is corrosion and block lifetime, but a conscientious watercooler will have taken measures to prevent this.

With that said, the block’s performance speaks volumes for how much promise it shows and with a few refinements this block goes from being one with promise to one that outright delivers. We’ll be having another closer look at the block again in a week or so, as we’ve got a custom-built overclocked and airbrushed Vadim PC to marvel at while we put it through a grilling in bit-tech labs. Oh, what tough lives we lead.

Addendum 1st Sept 2007, 11:02am: We've just been chatting to Vadim this morning some of the blocks details have changed since we last spoke to him:

- The Top Cover and Threaded Connecting Unit material in the current sample is anodised aluminium. The production run will be made out of brass.

- The screws supplied in the production units will be black and all cut to exact size so they don’t stick out of the VGA board too much.

- The bottom finish of the Copper Main Unit will be mirror polished and covered with a plastic to prevent oxidising

- The Top Cover will have written Blastflow on it.

- All production units will come pressure tested

- The product will come supplied with English instructions and there will be an extensive online FAQ and installation instructions on Blastflow.com for a variety of high end graphics cards as well as a dedicated technical support forum.

- The final product will be supplied in a 220x100x50 box

- The final product will come supplied with arctic silver 5 thermal paste.

- The o-rings will be cut to shape.

- The contact between the 2 parts should be made with arctic silver 5

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.